Caster Wheels and Their Importance in Industrial Use

Business News

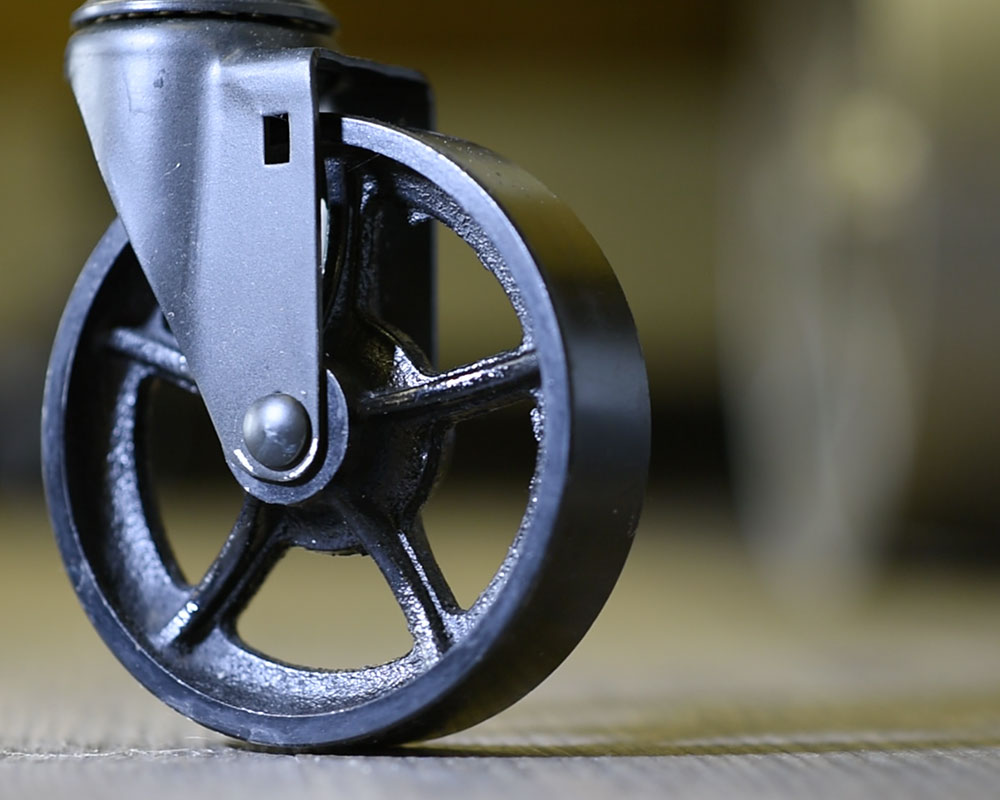

Caster wheels are used to move materials with ease and speed. They are also durable, corrosion-resistant, and easy to maintain. Read on to learn more about caster wheels and their importance in industrial applications. Caster wheels can make your job easier, whether in the manufacturing industry or just looking to improve your workplace.

Ensure Fast And Smooth Movement Of Materials

Caster wheels in industrial applications are designed to move heavy objects quickly and smoothly. They come in a wide variety of materials, shapes, and sizes. They are typically categorized according to their load-bearing capacity. Smaller caster wheels are ideal for lightweight objects, while larger ones are best for moving heavy machinery and objects.

Heavy-duty casters are typically used in manufacturing units and assembly lines for moving heavy materials. They are designed to move materials too heavy to move by hand. They are especially useful for moving items that weigh a few tons. They are used for moving anything from household goods to furniture. Caster wheels in industrial use are available with various bearings, including ball bearings, Delrin bearings, and plain bearings. Hard rubber caster wheels resist most solvents, chemicals, and oil.

They Are Corrosion-Resistant

Corrosion-resistant caster wheels are an excellent choice for industrial settings. These wheels are resistant to corrosion and are also highly durable. They can withstand salt, water, and cleaning agents. They can even withstand caustic solutions. They are available in two basic styles – plate-mounting and stem-mounting. The mounting style that works best for your needs will depend on the application you’re using them for.

Glass-filled nylon caster wheels are a tough, non-marking option. They’re corrosion-resistant and won’t flatten out under heavy loads. They’re also easy to start and last a long time. They’re corrosion-resistant and resistant to most chemicals, solvents, and oils. These wheels also operate well in extreme heat (+250deg F) and cold (+45deg F). Cast iron wheels are made from gray iron and are corrosion-resistant. Their heavy-duty design allows them to support massive loads and roll on steel or concrete surfaces. Cast iron wheels are also suitable for high-capacity applications and can withstand high temperatures. They can also withstand oil and mild chemicals.

They Are Durable

Caster wheels come in various materials, sizes, and shapes. They also come in different load-bearing capacities. Smaller wheels are designed for light objects, while larger wheels are best for moving heavy machinery. There are also different price ranges for caster wheels. Each type has its pros and cons. Some caster wheels are made from polyurethane, which provides high load capacity, excellent rollability, and excellent abrasion resistance. The material is typically molded around a plastic hub or a metal core. The hardness of polyurethane wheels depends on their specific application, but typically they range between 90 and 95 Shore A. These wheels are resistant to abrasion, corrosion, and extreme temperatures.

Caster wheels in industrial use are built to last a long time. Heavy-duty casters are made to handle a great deal of weight. They are beneficial for hospitals and other environments where mobility is essential. They offer smooth, easy movement for patients, supplies, and equipment. Without casters, modern hospitals and medical facilities could not function.

They Are Easy To Maintain

Proper maintenance of caster wheels is important for their longevity. Regular inspections will keep your casters in good condition and avoid a costly replacement. Check casters for deterioration monthly and check fasteners and gear to ensure they are secure. Also, lubricate casters every six months. Steel wheels are a good choice for industrial use, as they have excellent heat and abrasion resistance. Steel roller bearings can withstand up to 700degF. These wheels also have a high-temperature rating, which makes them more durable and longer-lasting. Pneumatic wheels are also available.

Caster wheels are used in many places. These wheels are common in school rolling carts, office chairs, and gurneys. They make moving heavy loads easier by reducing the amount of force needed.